Research and Development

Anti-Vibration

- Basic Theory of

Anti Vibration SystemMeaning of Anti Vibration System (AVS)

The main anti-vibration function is to prevent vibrations and noises generated from vibration sources of machines and vehicles not to be delivered to users and passengers, and its additional function is to enhance reliability and durability of machines and vehicles.

Theory

For the anti-vibration design under the vibration system

composed of vibration parameters m, c and k,

the vibration system is illustrated in the mathematical model

idealized in the degree-of-freedom system as shown

in the figure.The equation of motion of this system is indicated

in Newton's Second Law of Motion as follows:- inertia force (m: mass, kg)

- viscous resistance (C: damping coefficient, N/cm/s)

- spring restoring force (k: spring constant, N/cm)

- excitation function of external force

Characteristics of Rubber

It is a polymer that deforms when a weak force is applied at room temperature but restores to its original form when the external force is removed.

The substance in which the viscous property and the elastic property coexist ( Viscoelastic Polymer) → Elasticity: Load supporting function, viscosity: Impact absorbing function

Once vulcanized, the product cannot be reformed even if heat and/or pressure is applied.

In Vehicle Function of Anti-Vibration Product

- 1. Load Supporting Function (Stability)

- 2. Noise, Vibration and Harshness Performance (NVH Performance)

- One of technical evaluation indices on vehicle development

- One of key marketability factors

- 3. Vibration Insulation of Anti-Vibration Rubber

- Vibration insulation (blocking) role in the vibration

transmission path - One of important parts for sensible quality of vehicle

including stability, comfort and silence required by customers.

Importance of the anti-vibration rubber product keeps on increasing.

Anti-Vibration Product Reliability Improvement

Design

- Single product design

→ Secured system design capacity -

Development of durable system specifications

(Cooperation with customers)

Formulation

- Formulation technology enhancement

- High functional new material development

(such as high heat resistance)

Evaluation

- Single product evaluation verifiable of the actual car validity

- Implementation of a systematic durable test under actual car conditions

Production

- Mold design and production technology enhancement

- Automated and advanced production equipment

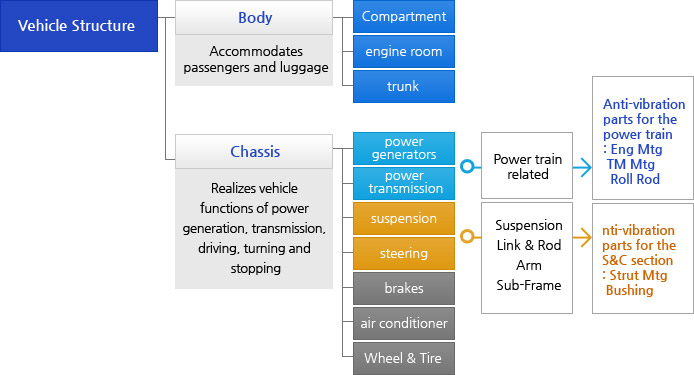

Anti-Vibration Part in Power Train and Chassis System

- Power Train Mount

POWER TRAIN MOUNT

Engine Mounting System

The engine and the T/M mount are mounted on the torque roll axis of

the power train, the whole power train weight is distributed and

the roll rod absorbs the reaction torque.Causes of torque generation are vibration due to engine explosion

and rotation, excessive engine movement controls

(such as quick start, quick braking, pot holes and road input),

and vibration due to engine torque change while driving.

Recently, the technology that ensures the vehicle performance with

3 mounts instead of the previous 4 mounts is developed and applied.TM MTG

ENG

MTGROLL

RODENG MTG

ACM

TM MTG

ROLL ROD

- Suspension & Chassis

SUSPENSION & CHASSIS

- Key Functions of Suspension

- Vehicle load support

- Shock absorbing function ⇒ Vehicle ride comfort (NVH)

- Tire road contact function ⇒ Vehicle ride and handling (R&H)

- Key Functions of Chassis

- Impacting shock reduction when passing speed bumps

- Road surface vibration insulation (NVH enhancement)

- Steering performance enhancement when turning

- Body running stability enhancement on quick braking.

Item Product Name Function ① FR SUBFRAME COMP It supports the lower structure, the engine and the transmission of the vehicle and absorbs their shock. ② LOWER ARM It supports the strut and the axle and absorbs their shock. ③ FR STAB BAR ASSY These suppress rolling of the vehicle. ④ LINK ASSY-STAB ⑤ FR SPRING Shock absorbers. These support the body and mitigate vertical impacts. ⑥ BRKT ASSY-STRUT,FR ⑦ RTN HOSE & TUBE ASSY The working fluid passage at the other side of pressurizing when steering. ⑧ PRESSURE HOSE COMP. The working fluid passage at the pressurizing side when steering. ⑨ FR BRAKE ASSY Brakes Item Product Name Function ① RR X/MBR ASSY It supports the lower structure, the engine and the transmission of the vehicle and absorbs their shock. ② RR UPR ARM These support the strut and the axle and absorb their shock. ③ RR ASSIST ARM ④ RR LWR ARM ⑤ RR STAB BAR ASSY These suppress rolling of the vehicle. ⑥ LINK ASSY-STAB ⑦ RR HUB BEAR’G The medium of the drive shaft and the entire wheel. ⑧ RR CARRIER ASSY Steering function and driving unit connection ⑨ RR DISC Braking disc ⑩ RR S/ABS ASSY The shock absorber. It supports the body and mitigates vertical impacts. ⑪ RR SPRING Large displacement control ⑫ RR S/ABS MTG BRKT ASSY Joined with the car body, it ensures the strut mobility. ⑬ RR BRAKE ASSY Brakes ⑭ RR PARK’G BRAKE ASSY ⑮ P/CABLE ASSY It delivers braking of the parking brake.